Avoiding methane emissions from a cassava starch factory and generating clean energy

Methane recovery in wastewater treatment (AMS.III-H); Grid connected renewable electricity generation (AMS.I-D)

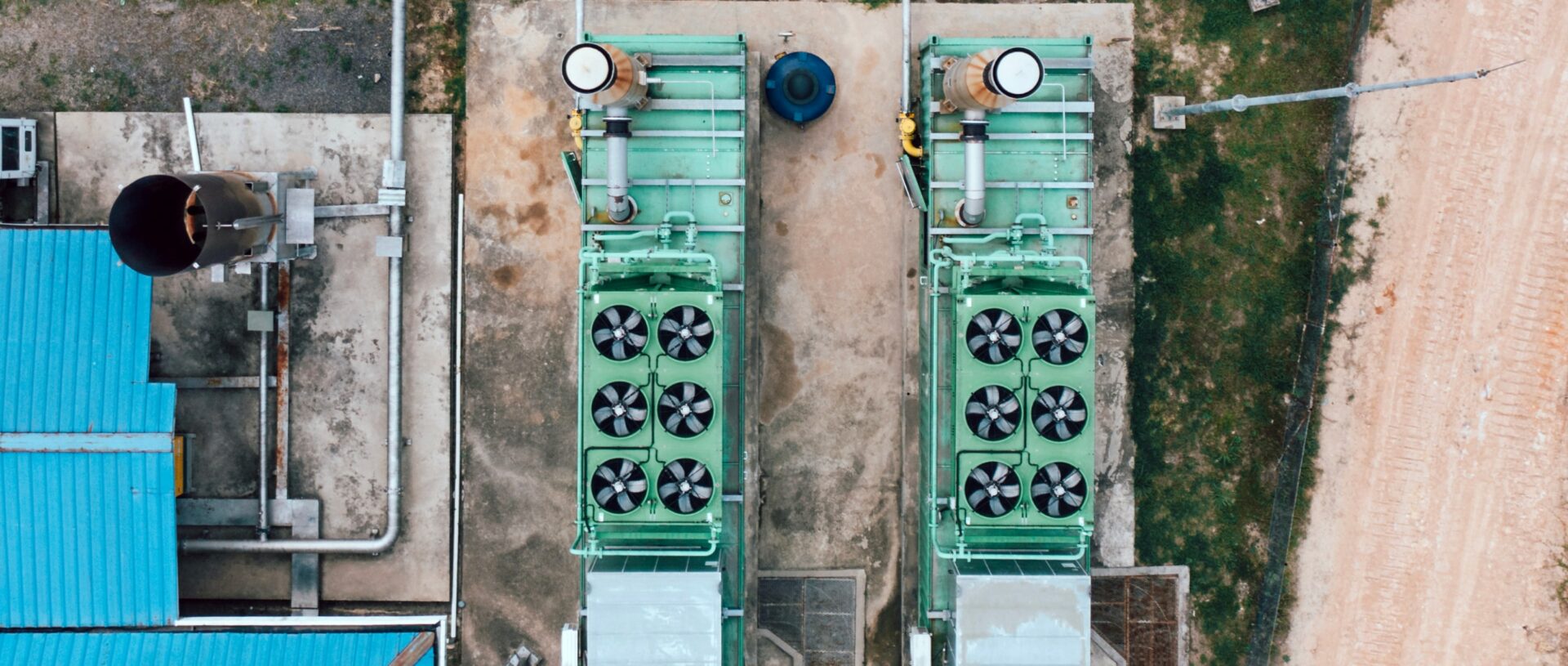

The Hamparan project treats the industrial wastewater of a cassava starch factory, captures its fugitive methane emissions and transforms these environmental liabilities into renewable energy which is then distributed by the national utility to 19 surrounding villages.

The expected verified emissions reduction is 30,327 tCO2 eq/year.

Discover the Sustainable Development Goals our Hamparan project fulfills:

Gree is the only B-Corp certified biogas solution provider in Asia

Gree Energy is B Corp certified and meets the highest standards of verified social and environmental performance. Our team has decades of combined experience in carbon emission expertise and resilient and regenerative food supply chains. We use world class industry standards including VCS, IFC PS, IRIS+, and SDG and our business model is supported by prominent international development agencies and organizations such as SCAF, FFEM, AFD, UKAID and IRENA.

30,327 tonnes of CO2e avoided (equivalent to emissions of 6,600 cars annually)

10,114,767 kwh delivered, enough to supply 18,000 people with clean and reliable

286,546 population - equivalent of industrial wastewater treated

97%+ organic pollution removed

4,275 tons of hydrogen sulfide emissions avoided

1,774 tons of methane emissions avoided

5,9 Million USD investment into rural area of Indonesia

Our biogas projects not only generate ESG impact but go beyond to demonstrate exceptional technical performance, encompassing energy output, efficiency, and reliability.

Commissioning

Verra’s validation

Feasibility study to produce natural fertilizers for the surrounding smallholding farmers

First issuance of verified carbon credits

Project in operations

Commissioning

Verra’s validation

Feasibility study to produce natural fertilizers for the surrounding smallholding farmers

First issuance of verified carbon credits

Project in operations

Hamparan Bumi Mas Abadi is a local Indonesian company that produces around 40,000 tonnes of native starch per year from cassava roots locally sourced from approximately 4,000 smallholder farmers. The cassava starch factory has been operational since 2009 and employs almost 100 workers.

Hamparan’s cassava starch factory passed Gree’s ESG safeguard standards:

Gree implements ESG safeguards of the project to strengthen the framework of a project, program or specific action and manage risks concerning the environment, governance and society.

Did you know the Hamparan Project reduces more than 30,000 tons of CO2 eq per year? Contact us to see how we can help your biogas project.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |